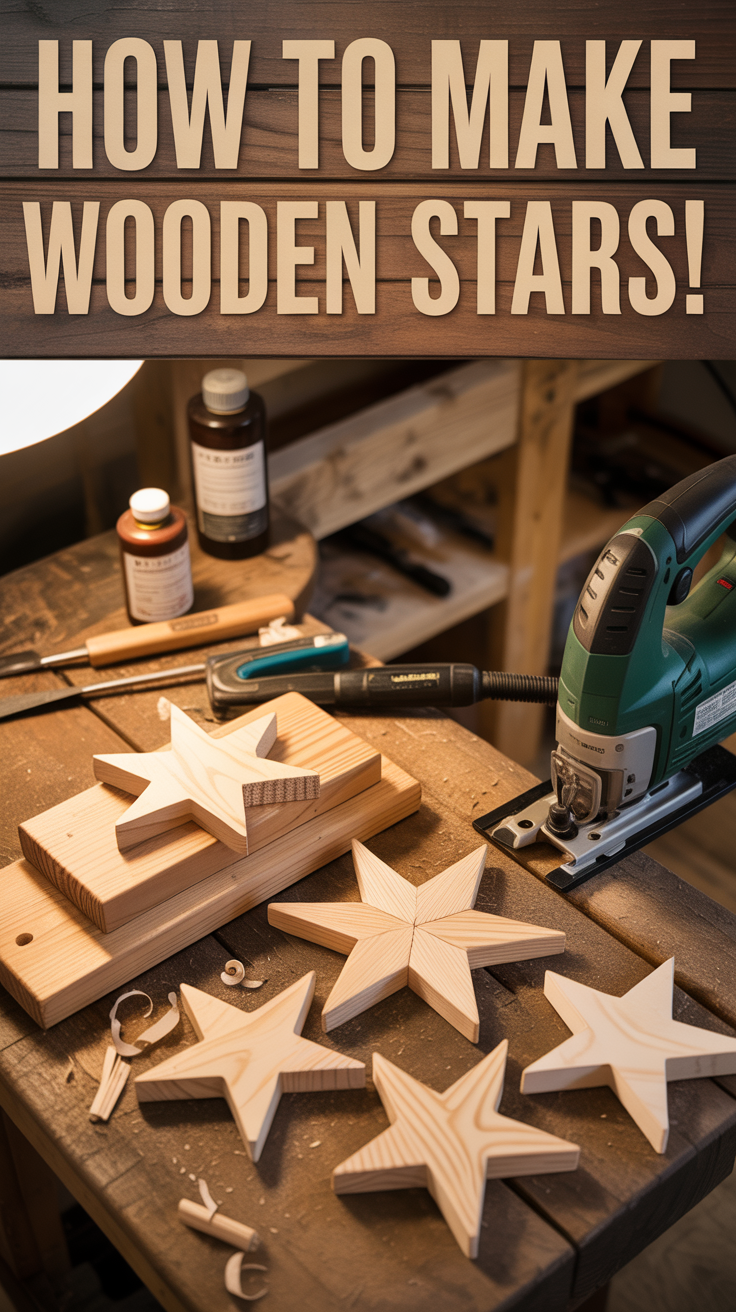

Wooden stars are timeless—equally at home as holiday ornaments, farmhouse wall decor, nursery accents, garden stakes, or rustic tree toppers. If you’ve been searching for a clear, beginner-friendly guide on how to make wooden stars, you’re in the right place. This tutorial covers simple flat stars you can cut in an afternoon, layered stars with added depth, and more advanced segmented or beveled versions that produce crisp, professional lines. We’ll also walk through materials, tools, safe cutting techniques, finishing ideas, and mounting tips so your stars look great and last.

Prefer ready-to-build plans with measured drawings? You can jumpstart your project with step-by-step templates from TedsWoodworking, which is especially useful if you want multiple star sizes or designs without doing the drafting yourself.

Whether you have a scroll saw, jigsaw, or bandsaw, you’ll find a method that fits your tools and skill level. Let’s get started.

Table of Contents

Essential planning for designs, sizes, and wood choice

Planning saves wood and frustration. Decide where your star will live and choose a design that fits your space and tools.

Star styles to consider

- Flat 5-point star plaque: One board, easy to layout, great for painted or stained finishes.

- Layered star: Two or three stars of descending sizes stacked with spacers for a dimensional look.

- Rustic slat star: Glued or nailed from reclaimed boards or pallet slats for farmhouse style.

- Segmented star outline: Built from mitered segments; clean, geometric, modern.

- Beveled “barn star:” Each point has a shallow pyramid bevel that catches light; intermediate difficulty.

Sizing guidelines

- Ornaments: 3–6 inches across.

- Shelf/wall decor: 12–24 inches across.

- Statement wall or barn star: 24–36 inches+.

- Outdoor display: Choose thicker stock (at least 3/4 inch) for durability.

- Pro tip: Scale stars by 125% increments (e.g., 8″, 10″, 12.5″) to create pleasing layered groupings.

Best woods for stars

- Easy finishing: Poplar, pine, alder.

- Strong and crisp edges: Maple, oak, ash.

- Beautiful grain: Walnut, cherry.

- Outdoor use: Cedar, cypress, redwood; seal thoroughly.

- For painted stars: Use inexpensive pine or poplar and save hardwoods for natural finishes.

Safety and wood properties

- Avoid splinter-prone boards for kids’ rooms.

- Check for knots and moisture that cause warping.

- Learn species characteristics at The Wood Database (thewood-database.com) for toxicity and finishing tendencies.

Before you cut, sketch or print your star at full scale. A crisp template is the single biggest factor for a crisp result. If you don’t want to draw by hand, look for downloadable patterns in plan libraries or consider TedsWoodworking for ready-to-go star templates and variations.

Tools and materials that make star-building easier

You can make wooden stars with very basic tools, but certain upgrades improve accuracy and speed.

Cutting tools (choose what you have)

- Scroll saw: Excellent control for tight points and clean inside curves.

- Bandsaw: Fast for thicker stock; use a fine-tooth blade for clean edges.

- Jigsaw: Good for larger stars; support the workpiece to reduce vibration.

- Miter saw or table saw with miter gauge: Essential for segmented star frames.

- Optional: CNC or laser for repeatability.

Marking and measuring

- Full-scale paper template printed and spray-mounted to the board.

- Pencil, sharp knife for scoring, square, ruler.

- Compass and protractor if drafting by hand.

- Digital angle finder for dialing in miters and bevels.

Workholding and support

- Clamps, double-sided tape or carpet tape for securing templates and parts.

- Sacrificial backer board for cleaner cuts and less tearout.

- Painter’s tape to reinforce fragile tips before cutting.

Sanding and finishing

- Sandpaper grits (120, 150, 180, 220).

- Small sanding blocks, detail files, or a sanding mop for tight points.

- Finishes: shellac or sanding sealer, water-based poly, oil-based poly, paint, stain, paste wax.

Hardware

- Keyhole hangers, D-rings, picture wire for wall mounting.

- French cleat for heavy stars or outdoor barn stars.

Materials checklist

- Wood board or slats (3/4 inch is a good default).

- Wood glue for layered stars or segmented frames.

- Brads or pin nails for quick assembly (optional).

Working in a compact shop? Smart layout, dust control, and foldable stations can be a game-changer. See ideas in UltimateSmallShop for step-by-step small-shop planning, space-saving benches, and budget tool recommendations that fit beginner to intermediate woodworkers.

How to make wooden stars with simple templates

The fastest way to perfect points is to cut a star from a single board using a printed template.

Draft or print your star

- Print at 100% scale using a free vector star generator or design software.

- For hand drafting, draw a circle (the star’s “diameter”). Mark five points around the circle at 72-degree intervals (use a protractor), then connect every second point to form the classic 5-point star.

- Spray adhesive the printout to the board or transfer the lines with carbon paper.

Prepare the board

- Mill a flat, square blank a bit larger than the template.

- Apply painter’s tape across the star tips to reinforce the fibers.

- For a painted star, pre-seal the board face with a light coat of shellac to reduce fuzz during cutting.

Cut the outline

- If using a scroll saw: Use a fresh fine-tooth blade (e.g., #5–#7) and keep a steady feed rate. Pivot just outside the point, then pare back to the line.

- If using a bandsaw: Use a narrow blade (1/4 inch or less) with higher TPI for cleaner tips. Approach points with relief cuts to avoid overshooting.

- If using a jigsaw: Clamp the work to a sacrificial board. Make short, controlled cuts into each point; it’s better to leave the line and sand to final.

Clean the tips and edges

- Use a sanding block to flatten each facet to the line.

- A small file or emery board cleans inside corners and tips.

- Progress through grits to 180–220 before finishing.

Optional: Add dimension

- Chamfer the edges lightly with a block plane or sanding block to create a beveled shadow line.

- Cut a second star 70–80% of the first star’s size, then glue it centered on top with 1/8 to 1/4 inch spacers for a layered look.

Accuracy tips

- Keep the template edge crisp—replace it if the paper fuzzes.

- Score along your cut line with a sharp knife before sawing to reduce tearout on cross-grain points.

- Practice on 1/4 inch plywood before moving to hardwood.

If you want a library of star templates in multiple sizes (and matching ornament, wall, and tree-topper patterns), check out TedsWoodworking. It’s especially handy when you need consistent sizes for sets or layered projects.

How to make wooden stars from segments and bevels

Segmented stars look clean and geometric and can be scaled easily. You’ll cut identical parts and assemble them into an outline or a layered “barn star.”

Segmented outline star (beginner to intermediate)

- Concept: Build the star’s outline from identical mitered sticks, then glue and clamp.

- Stock prep: Rip strips to uniform width (e.g., 1.5 inches). Joint and plane for consistent thickness.

- Determine miters: For a 5-point star, test scrap to dial in your miter angles. Use your printed template as a physical gauge—cut, place on the template, and adjust until seams match the lines perfectly. A digital angle finder speeds this up.

- Cutting jig: Use a stop block on your miter saw for consistent lengths. Mark parts so the grain direction and orientation stay consistent.

- Assembly: Dry-fit over your template. Use painter’s tape across joints to create “hinged” assemblies, then glue and fold. Clamp with band clamps or improvised cord clamps. Check against the template for squareness and point alignment.

- Reinforcement: Back the frame with a thin plywood star and glue for strength, or add hidden spline keys at miter joints if you’re comfortable with a table saw spline jig.

Layered beveled “barn star” (intermediate)

- Concept: Cut one or two flat stars, then add shallow bevels on the faces to create facets that meet at a ridge.

- Method A: Bevel after cutting. Tilt your table saw blade 10–15 degrees and use a tall auxiliary fence and a star-specific sled to support the work as you nibble shallow bevels into each facet. Test on scrap first.

- Method B: Build pyramids. For a deeper 3D look, cut ten isosceles triangles to form two shallow 5-sided pyramids (front and back). Glue each pyramid, then glue them edge-to-edge (or mount one pyramid to a flat backing). This requires careful angle setup—work from a mockup and a bevel gauge rather than memorized angles.

- Alignment: Mark the center of the star and lightly score layout lines so the peak of each bevel lands cleanly. Sand facets with a firm block to keep planes crisp.

Troubleshooting and tips

- If gaps appear at miters: Re-cut the ends with a fresh blade and check for burrs. Even tiny burrs push joints open.

- Springback: Stars assembled with tape “hinges” can spring. Use cauls and band clamps to keep the assembly flat while glue cures.

- Consistency: Make a story stick with your precise lengths and notes for future builds.

For segmented or beveled stars, accuracy comes from jigs and test pieces, not memorized measurements. Use your template as truth, adjust until it matches perfectly, then batch-cut all parts.

Clean cutting, sanding, and edge detailing for crisp points

Crisp tips and clean facets separate “handmade” from “homemade.” These techniques help you achieve professional edges.

Blade and bit choices

- Scroll saw: Fresh, fine-tooth blades for hardwoods; slower feed to reduce burning.

- Bandsaw: 6–10 TPI blades for hardwoods; higher TPI for thinner stock. Tension properly and set the guide bearings close to the work.

- Jigsaw: Use clean-cut or down-cut blades to reduce top-face tearout. Let the blade do the work—forcing curves wanders the cut.

- Table saw for facets: A high-tooth-count combination or fine crosscut blade leaves cleaner bevels.

Workholding and reduced tearout

- Always use a backer board when cutting tips; it supports fibers at the exit point.

- Masking tape along the cut line can help keep fibers together in softwoods.

- Score lines with a knife before cutting across the grain.

Sanding workflow

- Start at 120 to remove saw marks; move to 150 and 180 to refine; finish at 220 for clear finishes, or stop at 180 for paint.

- Use a hard sanding block on straight facets to avoid rounding edges.

- For tight inside points, try emery boards, needle files, or a foam sanding cone in a rotary tool at slow speed.

- A light pass with a card scraper can flatten facets without rounding.

Edge treatments

- Micro-chamfer: One or two swipes at 45 degrees with a sanding block softens edges and prevents paint chipping.

- Roundover: A 1/16–1/8 inch roundover on the back can help stars sit flat against the wall and reduce visible shadow defects.

- Burned edge effect: Kiss edges with a small torch, then brush with a stiff nylon brush for a rustic, grain-popped look. Seal afterward.

Dust and health

- Some woods cause irritation; use dust collection and a respirator. Reference species safety notes at The Wood Database.

- For machine safety guidance, review OSHA’s woodworking safety overview (osha.gov/woodworking).

Finishing ideas that make wooden stars stand out

Finishing brings your star to life. Choose a look that suits your decor or season.

Paint, stain, and glazes

- Painted farmhouse white: Prime, sand lightly, then apply two coats of acrylic latex or water-based enamel for durability. Distress edges with 220 grit for a vintage look.

- Stained hardwoods: Use pre-stain conditioner on blotch-prone woods like pine and poplar. Apply your stain, then topcoat with water-based polyurethane for a clear, non-ambering finish.

- Layered glaze: Over a base coat, apply a thin glaze in recesses to highlight depth, then wipe back.

Clear and natural finishes

- Shellac: Warm tone, fast-drying, easy to repair. Great as a sealer beneath topcoats.

- Oil-varnish blends: Wipe-on, forgiving. Multiple thin coats build a soft luster.

- Water-based poly: Durable, low odor, minimal color shift; good for light woods.

Rustic textures

- Wire-brushed grain: Use a brass brush along the grain, then stain; darker stain settles into the texture.

- Milk paint and wax: Chip-resistant, classic matte. Buff with clear or tinted wax to deepen color.

Outdoor protection

- Use exterior-rated paints or spar varnish with UV inhibitors. Recoat annually for sun-exposed stars.

- Seal end grain thoroughly; it’s the main pathway for moisture.

Color schemes

- Holiday sets: Red, green, and gold for Christmas; metallics or icy blues for winter decor.

- Americana: Red, white, and blue layered stars; add small stars or stripes to the largest layer.

- Nursery pastels: Soft grays, blush, and navy on layered stars for gentle contrast.

For in-depth finishing techniques (sanding sealers, film builds, and rub-out methods), Fine Woodworking’s finishing primers provide excellent fundamentals.

Mounting, displaying, and gifting your wooden stars

Once your stars look great, help them hang straight and last.

Wall mounting

- Keyhole slots: Rout a keyhole on the back so the star sits flush. Keep clear of thin tips.

- D-rings and picture wire: Easy and adjustable. Position so the star hangs level; mark center lines on the back.

- French cleat: Best for large/heavy stars. A 45-degree cleat anchored into studs provides rock-solid hold.

Free-standing and tree toppers

- Easel stand: Attach a small hinged leg to the back for shelf display.

- Tree topper sleeve: Glue a short dowel or metal tube behind the bottom point; ensure the top’s weight is centered to avoid tilting.

- Bases for tabletop stars: Cut a shallow dado in a small block, glue the bottom point in, and add felt feet.

Outdoor installs

- Pre-drill to prevent splitting. Use stainless or coated screws for longevity.

- Seal fastener holes with exterior caulk if needed.

- Add a small drip edge or mount with standoffs so water doesn’t sit behind the star.

Gifting and sets

- Bundle a set of three stars in graduated sizes.

- Personalize with a small burned monogram or date on the back.

- Package with kraft paper and twine for a rustic presentation.

If you’re outfitting a compact space to handle larger pieces like 24–36 inch barn stars, consider fold-away worktables and mobile bases—ideas you’ll find in UltimateSmallShop.

Creative variations and project ideas for every season

Make one star—or make a dozen. These variations keep the build fresh.

Holiday ornament stars

- Scale down to 3–4 inches. Use 1/4 inch plywood or thin hardwood.

- Drill a tiny hole before finishing; add twine or ribbon after the finish cures.

- Try metallic spray finishes or leafing for sparkle.

Rustic slat/barn wood star

- Cut five narrow slats and assemble directly over a full-size paper star template.

- Overlap joints and secure with brads; back with a thin plywood star for strength.

- Finish with a wash coat of diluted paint and an antiquing glaze.

Layered medal-style star

- Cut three stars (100%, 80%, 60%). Dye the smallest layer a bold color (e.g., navy), stain the middle layer dark, and leave the largest layer natural.

- Use 1/8 inch spacers between layers to create shadow lines.

Marquetry or inlaid star

- Cut a star recess into a contrasting wood panel, then inlay a different species star. Great for serving trays or plaques.

- Take your time scoring outlines and use a router inlay kit if you have one.

Pyrography and carving

- Burn line details along facets for a folk-art look.

- Chip-carve simple geometric patterns within the star’s planes.

Garden stake star

- Use rot-resistant cedar or cypress; round edges and seal thoroughly.

- Attach to a weatherproof stake with stainless screws; leave a small standoff to minimize water wicking.

For more decorative woodworking, see [DIY holiday woodworking ideas](INTERNAL LINK PLACEHOLDER) and build projects that coordinate with your stars.

Troubleshooting, safety, and pro tips

Everyone makes mistakes. The goal is to detect early, fix cleanly, and work safely.

Fixes for common issues

- Ragged tips: Cut slightly proud of the line, then true up with a block and fresh 150–180 grit.

- Tearout on the back: Add a backer board; use painter’s tape. Sand out minor defects and fill with tinted putty if painting.

- Gapped miters: Plane or re-cut ends; use a shooting board with a 45-degree fence for precise tune-ups.

Glue and clamping

- Use just enough glue to wet both faces—squeeze-out is inevitable, but you can minimize cleanup.

- Blue tape “clamps” work well for layered stars: tape the perimeter, apply glue, press, then add a few weights.

- Remove squeeze-out while gelled with a chisel or plastic scraper; avoid pushing water into the grain.

Accuracy and repeatability

- Keep a dedicated star template labeled with size and notes. Store it flat.

- Use a stop block and a digital angle gauge when batching segmented stars.

- Cut “setup sticks” for exact part lengths and keep them for repeats.

Safety essentials

- Eye and hearing protection; dust mask or respirator when sanding.

- Push sticks and finger-saving habits at machines. Review OSHA’s woodworking safety guidance (osha.gov/woodworking) for best practices.

- Maintain sharp blades; dull tools cause burning and kickback.

Wood movement

- Stars are small, but wood still moves. Avoid cross-grain glue-ups that trap movement, or use thin layers and flexible finishes.

- For a deep dive into wood behavior, see the USDA Forest Products Laboratory Wood Handbook.

Selling and side income

- Seasonal markets love stars, especially sets and personalized pieces.

- Batch efficiently: Cut multiples from a single template and spray-finish together.

- If you want to turn your hobby into a small business, explore pricing, sourcing, and simple marketing playbooks with WoodProfits.

Conclusion

Now you know how to make wooden stars in multiple ways—from quick template-cut plaques and layered styles to clean segmented outlines and beveled barn stars. With a solid plan, a crisp template, careful cutting, and a thoughtful finish, you’ll get sharp points, flat assemblies, and a look that suits any room or season. Use these methods to build ornaments, statement wall stars, or outdoor features, and keep a few templates on hand so you can batch stars for gifts or pop-up markets when inspiration strikes.

Want ready-to-print patterns and measured drawings to accelerate your builds? Browse TedsWoodworking. If you’re optimizing a tiny shop to make more in less time, UltimateSmallShop can help map out space-saving setups. And if you’d like to sell your stars, WoodProfits offers a gentle on-ramp to pricing and simple marketing.

FAQ

What is the easiest way to make a wooden star?

The simplest method is cutting a star from a single board using a full-scale paper template. Attach the template with spray adhesive, cut just outside the line with a scroll saw, bandsaw, or jigsaw, then sand to the line for crisp points.

Which wood is best for a beginner star project?

Poplar and pine are forgiving and affordable, making them ideal for painted stars. For a natural look with crisp edges, try maple. For outdoor stars, choose cedar, cypress, or redwood and seal thoroughly.

How thick should the wood be?

For wall decor and general use, 3/4 inch works well. For ornaments, 1/4–3/8 inch is sufficient. Outdoor or large stars may benefit from thicker stock for stiffness.

How do I get perfectly sharp tips?

Score the cut line with a knife, use a backer board, and cut slightly proud of the line. Finish to the line with a block or small file. Reinforcing tips with painter’s tape during cutting also helps.

How do I hang a wooden star on the wall?

For small to medium stars, keyhole slots or D-rings with picture wire are easy and stable. For larger/heavier stars, use a French cleat anchored into studs.