Why DIY kitchen builds are smarter than you think

A kitchen is the most-used workshop of your home. That’s why simple woodworking plans for kitchen upgrades—shelves, a cart, base cabinets, pull-outs—offer huge return on time and money. With a few sheets of plywood, basic joinery, and solid hardware, you can build durable, custom pieces that match your space, workflow, and style without needing a massive shop or expensive tools.

If you want a vetted collection of measured drawings, cut lists, and joinery diagrams, check out TedsWoodworking—it’s a large library of beginner‑friendly plans you can adapt to kitchen projects.

Table of Contents

Simple woodworking plans for kitchen layout and measuring

Great plans start with great measurements. Before you cut wood, capture the realities of your kitchen:

- Room measurements. Record wall lengths, ceiling height, window and door sizes, sill heights, and trim thicknesses. Note out-of-square corners—few kitchens are perfect rectangles.

- Fixed points. Locate plumbing, gas, outlets, and switches. Mark stud locations for future wall-mounts. A stud finder and painter’s tape help you map the wall.

- Appliance clearances. Fridges need ventilation space; dishwashers need level floors. Verify manufacturer clearances before you finalize cabinet widths or shelf spans.

- Human factors. Common heights: counters 36 inches; bar tops 42 inches; shelves 16–20 inches above counters; toe-kicks 3.5–4.5 inches high. Adjust for your family’s reach and accessibility needs.

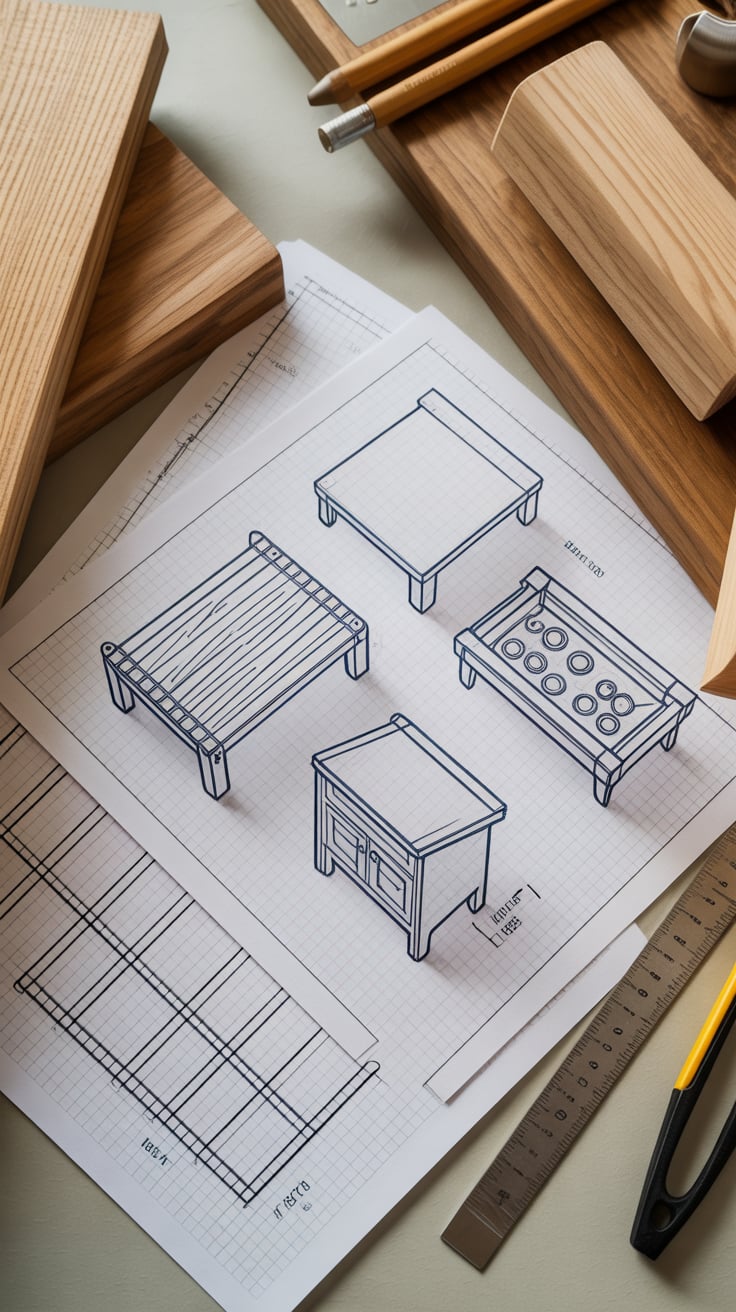

Sketch a plan. Grid paper or a simple drawing app lets you scale the room and experiment with placements. Use thirds or the classic working “triangle” (sink, stove, fridge) only as a guide—modern kitchens often use “zones” (prep, cook, clean, coffee station), which influence where shelves, carts, and pull-outs actually help.

Design principles that keep builds “simple”:

- Modular widths. Build in common increments: 12, 15, 18, 24, 30 inches. That makes hardware and accessories easy to source, and sheets cut efficiently.

- Repeatable parts. Standardize panel heights and depths to reuse fence settings.

- Flat, square assemblies. Simple butt or pocket joinery is fine if your parts are true.

Two important checks before cutting:

- Scribing allowance. Walls rarely run straight. Leave 1/2 inch extra on fillers or side panels to scribe to the wall for a no-gap install. [

- Opening sizes. Test your path from shop to kitchen. A rigid 34-inch-deep cabinet might not turn a hallway corner—assemble boxes in-room if necessary.

Finally, decide finish and style early—painted vs. clear finish affects material choices (MDF vs. veneered ply vs. hardwood) and joinery visibility. It also determines prep steps, like edge banding or face frames, covered in later sections.

Materials, joinery, and hardware that stand up to kitchen life

Kitchens are humid, busy, and occasionally messy. Your material and joinery choices should reflect that.

Smart sheet goods:

- Plywood. Choose cabinet-grade, void-free plywood (birch, maple, or prefinished) for carcasses. 3/4 inch for sides and structural parts; 1/2 inch for backs or drawer boxes. Prefinished interiors speed projects and clean easily.

- MDF. Flat and smooth—great for painted doors and face frames—but avoid under sinks or anywhere with moisture exposure. Seal edges thoroughly under paint.

- Melamine. Easy-clean and budget-friendly, but edge banding is a must and screws need special care to avoid blow-out.

Helpful solid woods:

- Maple, birch, poplar. Stable, easy to machine, and affordable for frames and doors. Oak and ash work for a rustic kitchen aesthetic.

- Softwoods. Pine works for utility shelves or carts, but plan for dents; seal with a durable topcoat.

For wood movement and durability guidance, see the U.S. Forest Service’s Wood Handbook.

Joinery you can trust:

- Pocket screws. Fast and strong for face frames and cabinet boxes when used with glue and proper clamping.

- Dados and rabbets. Simple router or table-saw cuts that increase strength and alignment. Ideal for shelves and cabinet backs.

- Confirmat or cabinet screws. Excellent for sheet goods; pre-drill for clean results.

- Dowels and biscuits. Helpful for alignment; biscuits aren’t structural, but they speed face-frame assembly.

Hardware choices that make a difference:

- Full-extension drawer slides (undermount or quality side-mount) let you access the entire drawer. Soft-close reduces slams.

- Euro-style concealed hinges for adjustability and a clean look.

- Shelf pins for adjustability; metal pins beat plastic in the kitchen.

Finishes for a kitchen:

- Painted builds: waterborne acrylic enamel or waterborne alkyd for toughness, quick dry, and low odor.

- Clear builds: waterborne polyurethane, wiping varnish, or hardwax oil for a warm, natural feel.

- Food-contact areas: consider mineral oil, pure tung oil, or shellac when a surface will touch food, like a cutting board insert. For a primer on food-safe approaches, see Popular Woodworking’s Food-Safe Finishes.

Always follow safe shop practices. Consult OSHA’s Woodworking Safety basics for dust control, hearing, and blade guarding.

Open shelves and spice storage you can build in a weekend

Open shelves deliver instant storage and style while being one of the simplest builds. Two sturdy brackets, a straight shelf, and careful mounting—and your kitchen gains useful real estate.

A reliable open-shelf plan:

- Shelf size. Depth 10–12 inches keeps items accessible without dominating the workspace. Thickness 3/4 inch with a front edge 1.5–2 inches (apply a false edge strip or build a thicker “torsion” look) for rigidity.

- Material. 3/4-inch maple ply with iron-on veneer edge banding; or glue up 1-by hardwood boards for a solid shelf.

- Mounting. Hit at least two studs. If stud spacing doesn’t match, run a hardwood cleat first, anchored into studs, and attach brackets to the cleat. For drywall-only spans, choose heavy-duty anchors rated for your load; see Family Handyman’s guide to wall anchors.

Build steps:

- Cut shelves to length; apply and trim edge banding or glue on a solid-wood nosing.

- Sand through 180–220 grit; break edges lightly.

- Finish both sides before install for moisture balance.

- Locate studs; level and mount brackets or the cleat.

- Fasten shelves from below through brackets with short screws.

Load planning. A 36-inch shelf into two studs with robust brackets easily holds spices, mugs, and bowls. If you plan to store heavy cookware, upgrade to thicker material and closer bracket spacing.

Slim spice rack inside a cabinet door:

- Build a shallow frame (2.5–3 inches deep) with rails and small dowel fronts to retain jars.

- Mount with short screws that won’t penetrate the door face; always pre-drill.

- Alternatively, create a pull-out spice tower: a 5-inch-wide box running on 100-lb full-extension slides between two cabinets or beside the range.

Coffee station shelf set:

- Stagger three shelves at 14, 24, and 34 inches above the counter to clear appliances.

- Route a shallow cable channel at the back underside and add a cord clip to manage wires.

Simple woodworking plans for kitchen base cabinets

Base cabinets are the backbone of kitchen storage. Keep the plan simple, modular, and square—and you can build a run of boxes in a weekend, then add doors, drawers, and trim as time allows.

Frameless vs. face-frame

- Frameless (Euro): 3/4-inch plywood carcass, edge-banded, with adjustable hinges and slides attached directly to the sides. Maximizes interior space and speeds construction.

- Face-frame: A 3/4-by-1.5-inch hardwood frame covers plywood edges, adds racking strength, and gives a classic look. Great if you plan to paint.

A simple 24-inch-deep, 34.5-inch-high, 24-inch-wide base cabinet plan:

- Sides: 2 pieces, 34.5 by 23.25 inches (depth assumes 3/4-inch back and 1-inch setback for toe-kick if desired).

- Bottom and top stretcher: 23.25 by 22.5 inches (sized to fit between sides; confirm your own material thickness).

- Back: 1/2-inch plywood, 23.25 by 30 inches (stops above toe-kick).

- Toe-kick: 3.5 inches high base frame, or notch sides to form the kick.

- Shelf: 23 by 22.5 inches adjustable on pins.

Joinery, the simple way:

- Rout or saw a 1/4-inch dado for the back; or overlay a 1/2-inch back for extra stiffness.

- Use pocket screws with glue to join bottom and stretchers to the sides, clamped flat.

- Square the box; fasten the back to lock it.

Doors and drawers:

- Doors: 1/2-inch overlay Shaker is beginner-friendly—rails and stiles with a flat panel. Paint-grade poplar frames with a plywood panel are forgiving.

- Drawers: 1/2-inch plywood boxes with a 1/4-inch bottom set in a groove. Use full-extension slides sized to interior depth.

Installation:

- Build a level base with shims or a ladder-style platform.

- Screw cabinets to studs through the backs or hanging rails; clamp face frames together and join with pocket screws.

- Keep reveals even; adjust hinges after doors go on.

Edge options:

- For painted frameless, iron-on banding and a light radius from a block plane make edges look pro.

- For a traditional look, add a 1/4-by-3/4-inch applied bead to the face frame.

This basic module adapts to different widths (12–36 inches) so you can mix drawers, doors, and pull-outs where they help most.

Rolling island or utility cart with butcher-block top

A rolling island multiplies prep space and storage without remodeling. Build a sturdy cart sized to your room, then top it with hardwood or a purchased butcher-block panel.

Recommended size and layout:

- Footprint: 20–24 inches deep, 36–48 inches wide for two-sided access; height 36 inches to align with counters.

- Base: An H-frame of 1.5-by-2.5-inch hardwood aprons joined to 2.5-inch square legs with pocket screws or mortises; add a lower shelf.

- Top: 1.5-inch-thick hardwood panel (maple or beech). For cutting-friendly use, consider a separate cutting board insert so the entire top doesn’t need frequent resurfacing.

- Casters: Two locking swivel and two fixed, rated for the total load of the cart and contents.

Build sequence:

- Mill legs square; cut aprons and stretchers to length. Pocket-hole the aprons on their inside faces.

- Assemble the base; ensure it’s square. Add a 3/4-inch plywood lower shelf set into dados or sitting on cleats.

- Install a center divider and two drawer runners if you want a drawer bank on one side; otherwise, add open shelves with rails to prevent items from sliding off when rolling.

- Sand, then apply a durable finish. For the base, waterborne enamel or polyurethane resists scuffs; for a food-adjacent top, use a hardwax oil or mineral oil plus wax on a removable cutting board.

- Attach the top with elongated holes or figure-8 fasteners to allow seasonal movement.

Mounting accessories:

- Towel bar on one end doubles as a push handle.

- Hooks for pans or utensils along an apron.

- Optional spice rail around the top as a subtle edge.

Working in a compact space? Efficient layouts and fold-down surfaces make a tiny shop productive. If you’re setting up or optimizing a small workspace, UltimateSmallShop – The Next Woodworking Blockbuster! shows practical, budget-friendly shop setups that help you build kitchen projects even in tight quarters.

Drawers, pull-outs, and organizers that transform storage

Cabinets are only as good as their interiors. Simple, modular organizers can double usable space and cut kitchen stress.

Full-extension drawers

- Materials: 1/2-inch plywood sides, 1/4-inch plywood bottom in a 1/4-inch groove 1/2 inch up from the bottom.

- Joinery: Glue and nails or pocket screws; square carefully.

- Faces: Oversized to create the overlay you want; attach from inside with temporary screws, then adjust and fix permanently.

Trash and recycling pull-out

- Width: 15–18 inches for one bin; 18–24 inches for two.

- Build a 3/4-inch plywood tray with a 1.5-inch rail front and back; notch for the slides you choose.

- Mount heavy-duty slides (100-lb) to the cabinet sides. A front false drawer panel becomes the pull-out face.

Baking sheet organizer

- Create vertical slots in a 12-inch cabinet using 1/4-inch plywood dividers captured in saw kerfs on the top and bottom panels.

- Alternatively, buy a wire rack and build a simple frame to mount it.

Cutlery and utensil trays

- Custom-fit shallow trays with 1/4-inch plywood bottoms and 1/2-by-2-inch dividers. Dry-fit with your actual utensils to confirm spacing before gluing.

Spice pull-out and narrow fillers

- A 6-inch-wide pull-out beside the range stores oils and spices. Use side-mount slides; add side rails or dowels to keep jars secure.

Pantry roll-outs

- Retrofit deep base cabinets with stacked roll-out trays on full-extension slides. Keep 3-inch vertical spacing for canned goods, 6–10 inches for pots and small appliances.

Labeling and maintenance

- A label maker and clear bin fronts help everyone return items to the right spot.

- A yearly tune-up—tightening slide screws and hinge plates, re-waxing drawer runners—keeps everything gliding.

These organizers are quick builds using scrap offcuts and standard slides. They also make the most of narrow or awkward cabinet bays that stock solutions don’t fit.

Finishing and installation for durable, food-adjacent surfaces

Finishing is where your projects become kitchen-grade.

Surface prep

- Sand progressively: 120, 150, 180. Stop at 180 for paint; go to 220 on clears.

- Caulk small gaps in painted face frames; avoid caulk where wood movement is expected.

- Raise grain before waterborne finishes: damp rag, dry, then final sand.

Painted finishes

- Primer: Bonding primer over MDF or knot-sealed softwood; shellac-based primer stops tannins on oak or pine.

- Topcoat: Waterborne enamel or urethane-alkyd; spray for best results or use a high-quality microfiber roller and brush for edges.

- Between coats: Light scuff with 320 grit; vacuum and tack.

Clear finishes

- Waterborne polyurethane: Low odor, non-yellowing on light woods, durable for cabinets and shelves.

- Wiping varnish: Easy to apply; builds a warm sheen but cures slower.

- Shellac: Beautiful and food-safe when cured, but heat and water can mark it; ideal for drawer interiors or lightly used items.

- Mineral oil + wax: Best for cutting boards or removable insert blocks; reapply regularly.

Food safety note: Most modern film finishes are considered safe for indirect food contact once fully cured; for cutting surfaces, stick to non-film options like mineral oil/wax. See the overview at Popular Woodworking’s Food-Safe Finishes.

Mounting, scribing, and leveling

- Walls are rarely straight. Use a compass to scribe fillers or side panels to the wall, then plane to the line for a tight fit.

- Level runs of cabinets using shims and a long straightedge; screw to studs through broad washers or hanging rails.

- For shelves and upper cabinets, hit studs whenever possible and verify fastener length and anchor ratings relative to your loads; see Family Handyman.

Ventilation and durability

- Seal the undersink cabinet with a moisture-resistant coating; add a shallow drip tray.

- Use bumpers and soft-close hardware to minimize finish dings.

- Consider edge guards or thicker nosing on frequently bumped edges like island corners.

Work safely—good dust collection and PPE matter for a clean finish and your lungs. Reference OSHA’s Woodworking Safety for key practices.

Recommended resources for plans and small-shop success

- For a wide catalog of measured drawings you can adapt to cabinets, islands, and organizers, browse TedsWoodworking. It’s handy when you need multiple looks or dimensions for the same project.

- If you’re building in a garage, apartment, or shared space, UltimateSmallShop – The Next Woodworking Blockbuster! helps you plan tool choices, layout, and dust control so you can produce cabinet-grade pieces even with minimal square footage.

- Thinking about turning your kitchen builds into a side income—pull-outs for neighbors, coffee carts, or floating shelves? WoodProfits shares straightforward business basics so you can price, market, and deliver without guesswork.

These resources complement the measured plans and build steps in this guide so you can move from idea to install with fewer do-overs.

Conclusion

Simple woodworking plans for kitchen projects are the fastest way to add custom functionality and style without a full remodel. Start with accurate measurements and modular designs, use durable materials and straightforward joinery, and focus on a few high-impact builds—open shelves, a base cabinet or two, a rolling island, and smart pull-outs. With consistent finishes and careful installation, your DIY pieces will look intentional, perform daily, and grow with your space. When you’re ready for more designs or shop efficiency tips, the plan libraries and small‑shop resources above will help you keep building.

FAQ

What tools do I need to follow simple woodworking plans for kitchen projects?

A circular saw with a straightedge, drill/driver, pocket-hole jig, random-orbit sander, and a router for dados will handle shelves, cabinets, and organizers. Add clamps, a stud finder, and a level for installs.

Which wood is best for kitchen cabinets if I’m painting?

Use cabinet-grade plywood for boxes and poplar or maple for face frames and Shaker doors. MDF also paints very well for doors and panels—just seal edges thoroughly.

Can beginners build a base cabinet that looks professional?

Yes. A frameless 24-inch module with pocket screws, a 1/2-inch back, and full-extension slides is beginner-friendly. Focus on square parts, careful sanding, and good hardware alignment.

How do I finish shelves and cabinets for kitchen durability?

Waterborne polyurethane or waterborne enamel resists moisture and stains. For food-contact cutting surfaces, stick with mineral oil and wax; for food-adjacent areas, fully cured film finishes are fine.

How do I mount open shelves safely if studs don’t line up?

Run a hardwood or plywood cleat into the studs, then mount brackets to the cleat. If you must use drywall anchors, choose anchors rated for your load and verify wall condition.